Atomic layer deposition: a precision tool for nanomaterial engineering

- General Information

- Symposia

- Atomic Layer Deposition

- Biomaterials and Polymers

- Characterization and Metrology

- Luminescence Phenomena: Materials and Applications

- Microelectronics and MEMS

- Multifunctional and Magnetic Materials

- Nanostructures

- Plasma and Vacuum

- Renewable Energy: Materials and Devices

- Semiconductors

- Tribology, Surfaces and Interfaces

- Theory and Simulation of Materials

- Thin Films

- Science Outreach

- General Program

- Plenary Lectures

- Short Courses

- Technical Talk

- Congress Registration

- Second Athletic Race Registration

- Posters

- Abstract Submission 2024

- Commitees

- Fees

- Hotel Accomodation

- Awards/Grants

- Sponsors and Exhibit

- Book of Abstracts

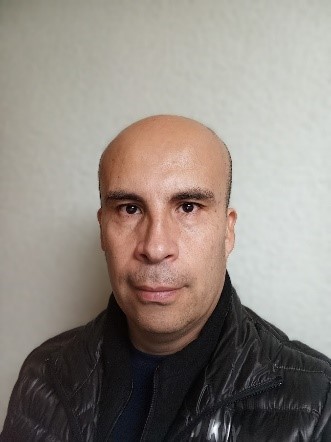

Hugo Tiznado

In 2004, he graduated in the area of catalysis from the PhD program in Physics of Materials (currently Nanosciences) at CICESE and CNyN-UNAM. Subsequently, he completed a three-year postdoctoral stay in the Department of Chemistry at the University of California Riverside, where he investigated surface reaction mechanisms during the growth of thin films using the atomic layer deposition (ALD) technique. In 2007, he joined the CNyN-UNAM, where he currently holds the position of Senior Researcher B and is ranked at level 2 of the SNII.

His line of research focuses on the Fabrication of Nanostructures with Controlled Properties, mainly using the ALD technique for synthesis. He employs a bottom-up approach to achieve the precise growth of structures at the molecular level, taking advantage of self-limiting reactions on the surface of precursor molecules. Applications of interest include energy storage in solid-state devices, waveguides, optical filters, catalysis, and more recently, self-assembled molecules (SAM’s) for area-selective ALD. He has published more than 100 scientific papers.

Atomic layer deposition: a precision tool for nanomaterial engineering

Nanotechnology, driven by the pursuit of novel materials with tailored properties, hinges on precise control over nanoscale structures. ALD, a versatile deposition technique, offers unparalleled precision for surface engineering, enabling the creation of nanomaterials with meticulously controlled composition, thickness, and morphology. By alternating between self-limiting gas-phase reactions, ALD ensures atomic-level control over the deposition process, allowing for the fabrication of nanostructures with exceptional uniformity and reproducibility. This workshop will dive into the fundamental principles of ALD, template assisted nanostructures, control of material properties, photocatalysis, energy storage, optical coatings with tailored refractive indices, selective atomic layer deposition.

Participants will gain a comprehensive understanding of ALD and its potential to drive innovation in various technological domains.